The New Xuanyi Disassembly of the Disassembly Workshop Comments on the Model of Exam-oriented Education

【Chexun. com reported】 What is exam-oriented education? Educational thoughts and educational behaviors aimed at coping with entrance examination test test students’ academic level by the rate of entrance examination. So, what about the design, workmanship and exam-oriented education of vehicles? Why did the editor make such an evaluation? Take it easy, let’s take our time.

Points are the lifeblood of students; I believe that anyone will have a deep feeling about this. No matter what personal ability, everything depends on the hero of exam scores. A high score is a "good student" and a failure is a "bad student". Bump, the lifeblood of a car; For automobile products, it is also facing the test of various crash tests. If a model with outstanding appearance performance but low crash score is placed in front of you, it is estimated that it will not be purchased. Getting a high C-NCAP collision score in China is like getting a diploma from a famous university, so it’s no wonder that those who get an overseas NCAP diploma are complacent. Naturally, parents are also full of face and confidence. But exams are dead, and people are alive. Some parents will be "smart" to teach their children how to cope with the exam content. Next, we will learn what the new Sylphy students have learned under the guidance of "parents". Has morality, intelligence, physique, beauty and labor been fully developed?

Bumper structure score before vehicle protection: 6 points

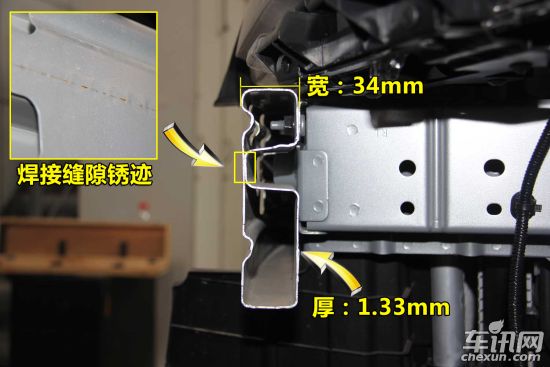

The new Xuanyi bumper structure is composed of bumper skin, low-speed cushioning foam and metal bumper iron with energy-absorbing box, which is made of iron. Aside from the boring data, the quality of the bar iron can not be distinguished from the thickness, which is also directly related to the structure and material. Generally, our common bumper is made of iron. Considering the lightweight design, the models will be made of aluminum alloy, and the structural design of bar iron is mostly bow-shaped. We can clearly see that the front joint of the bumper has rusted, but it will not affect its function.

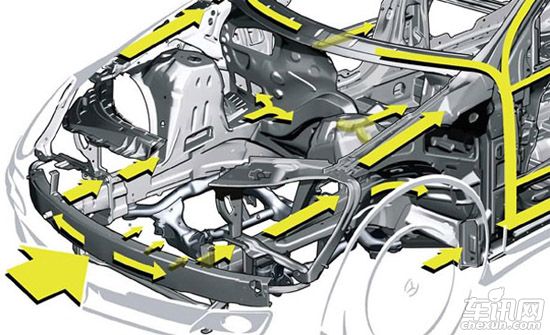

The energy-absorbing box is also a good companion of bumper iron. At present, most of the dismantled models will have energy-absorbing boxes behind bumper iron. The function of energy-absorbing box is unusual. In the actual collision, it is mainly folded and absorbed by this component to transfer collision energy. To maximize the protection of the body rail and other important components. Bumpers and energy-absorbing boxes are like the muscle tissue of human body, and they hit the muscular man and the sparerib man equally. If the ribs of the sparerib man are broken, the muscular man may be safe. When the strength is too great for the anti-collision beam and energy-absorbing box to bear, it is necessary to rely on the structural strength of the car body to resist. When it is hit by a large force, the role of the bumper is only 10%. The most solid part is the car skeleton, like the human skeleton. As for the new sylphy skeleton, we will introduce it later.

Careful netizens will find a problem. Is it strange to connect the energy-absorbing box? The following picture of the new sylphy bar iron is the new sagitar bumper structure. Observing that there is no gap between the energy-absorbing box and the flange, it is a face-to-face connection, while the new sylphy adopts a point-to-point connection. At this time, a question arises in the editor’s mind. For a single bar iron structure, if this connection mode collides, will it cause the energy-absorbing box and the flange to fall off, thus affecting the energy-absorbing effect?

FAW-Volkswagen new sagitar bumper iron

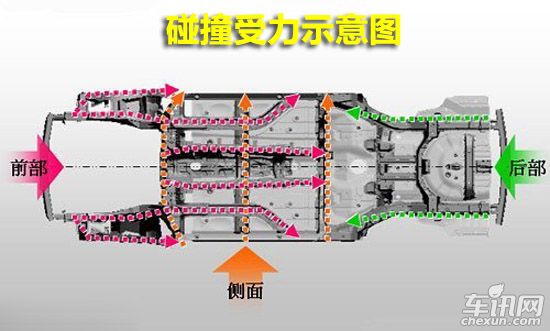

Just now we mentioned the problem of collision force transmission, and we will continue to consolidate this concept here. The front is impacted, and the front bumper distributes the force to the energy-absorbing boxes on both sides, and then transmits it to the left and right front side rails, and then to the vehicle body. The front longitudinal beam is the only medium between the bumper and the middle of the car body. In order to ensure the uniform dispersion of the force, the size and strength of the common left and right front longitudinal beams are designed to be the same. But have you ever heard that the left and right longitudinal beams are not as thick as each other? Don’t be surprised, the new sylphy is!

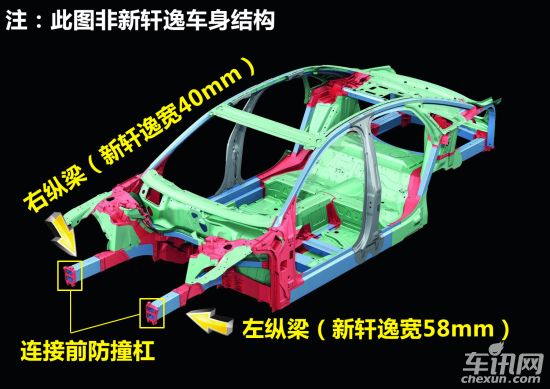

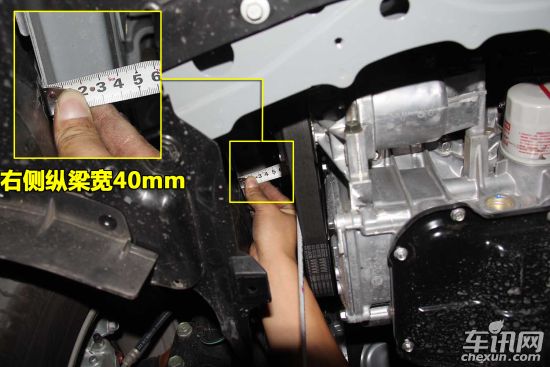

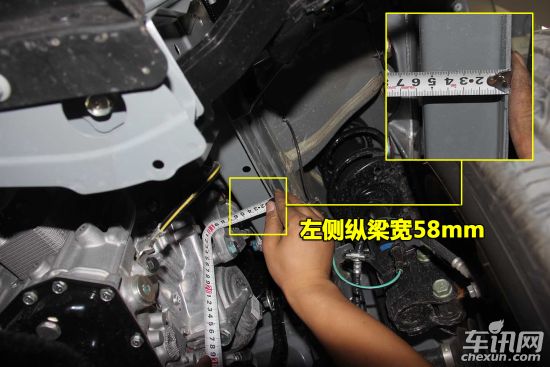

The width of the left longitudinal beam of XinXuanYi is 58mm, and the width of the right longitudinal beam is 40mm. Why is the difference so wide? Is it the design requirement or something else? Before the analysis, let’s get familiar with the test items of C-NCAP. C-NCAP mainly tests the frontal collision test of 100% overlapping rigid barrier, frontal collision of 40% overlapping deformable barrier (driver’s side) and lateral collision test of deformable moving barrier. Does the red font attract your attention? The position of 40% offset collision is the driver’s side, that is, the left side. Can we think that the left longitudinal beam is designed to be wider because of the greatest impact force in the event of collision, and the right longitudinal beam is not in the scope of examination, which can save materials? If the 40% offset collision is increased on the right side, what about the performance of the new Sylphy? This problem can only be explained by the manufacturer.

Editor’s summary: The structural design of the front bumper is special in that the energy-absorbing box is connected point to point, and there is doubt about the firmness during collision; I personally think that the design of the front longitudinal beam with different thicknesses is this "lightweight" an innovative design? Imagine if the right side 40% offset collision test is added, will the existing structural design be continued?