Arm plastic chip is 0.8μ m in Nature, the first flexible native 32-bit microprocessor.

On July 23rd, local time on July 21st, Arm’s first 32-bit microprocessor Plastic based on flexible plastics was published in the top academic journal Nature.

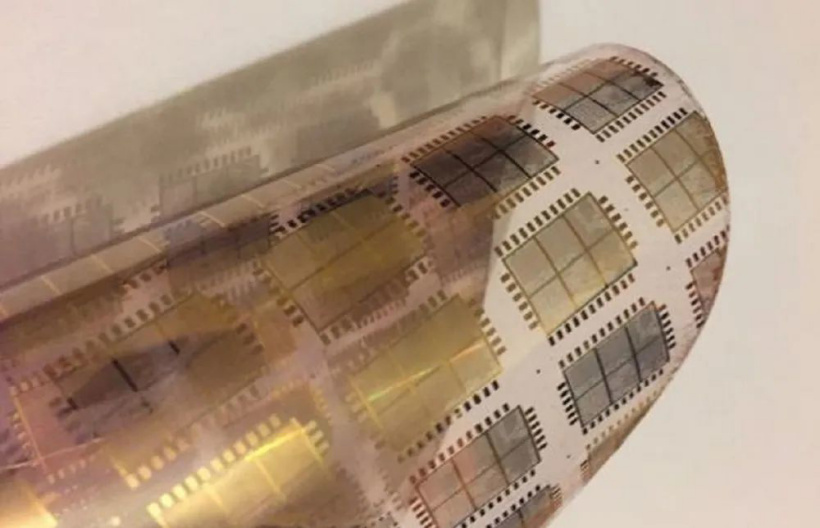

PlasticARM consists of 56340 NMOS(N-type metal-oxide-semiconductor) transistors and resistors. PlasticARM adopts thin film transistor (TFT), which can be bent to a radius of curvature of 3 mm..

This microprocessor is manufactured by PragmatIC, a British flexible IC manufacturer invested by Arm. It adopts FlexLogIC 200mm wafer process, and the chip process is 0.8μm, which has the potential of low-cost mass production.

In the past 20 years, there have been low-cost flexible solutions for memory, sensors, batteries and light-emitting diodes. However, as for microprocessors, people can only integrate the silicon-based microprocessor die on the flexible substrate, thus obtaining a flexible microprocessor. However, this scheme needs to adopt the traditional chip manufacturing process, and the cost is too high, which is far from meeting the requirements of intelligent daily necessities.

According to the paper, PlasticARM does not want to replace the traditional silicon-based chip, but it can really make daily necessities such as beverage bottles, food packaging, clothing, bandages and wearable devices intelligent.

▲ Mike Muller, CTO of ARM at that time, was showing samples of plastic chips.

Based on this, as early as 2015, Arm revealed the research and development plan of the system on a plastic chip (SoC) based on Cortex M0. On November 24th, at Arm TechCon, Mike Muller, then CTO of ARM, showed samples of plastic chips. He also hinted that this design can be applied to low-power application scenarios such as the Internet of Things.

During the event, Mike Muller had a telephone conversation with Scott White, CEO of PragmatIC. But PragmatIC was still busy developing an analog component library at that time, and its timetable was not clear.

Time has passed today, and the flexible plastic microprocessor that has been running for 6 years has finally been officially published. Does this mean that the pace of the fully intelligent era is approaching?

PlasticARM is manufactured in its fab-in-a-box wafer factory in Sedgefield, England, using the 0.8μm process of PragmatIC.

According to the researchers, PlasticARM has more than 18,000 logic gates, which is 12 times higher than the previous flexible integrated circuit, and it is by far the most complex flexible integrated circuit. On the basis of Plastic, people can build a low-cost, flexible intelligent integrated system and realize the real "Internet of Everything".

PlasticARM is not perfect either. It is reported that Arm is developing a low-power unit library, which can support plastic design of up to 100,000 doors to solve the heat dissipation problem of flexible plastics. However, practical NMOS technology may not be able to realize the migration of 100,000 gates, and CMOS technology is needed, which may take several years.

Nevertheless, researchers predict that in the next decade, PlasticARM will integrate more than 1 trillion products into the digital world, bringing reform opportunities for life, scientific research, business and other dimensions.

Compared with the commonly used metal-oxide-semiconductor field-effect transistor (MOSFET), Arm adopts thin film transistor (TFT), which has obvious advantages in thickness, integration and manufacturing cost.

In the manufacturing process, the researchers chose flexible electronics manufacturing technology, which is also known as the naturally flexible processing engine. The metal oxide thin film transistor manufactured by this technology has low cost and the size also meets the requirements of large-scale integration.

▲ flexible Arm Cortex-M SoC with I/O.

It is worth mentioning that PlasticARM is more universal than the recently released flexible machine learning hardware, and also supports a rich instruction set, which can be used to write various applications such as machine learning.

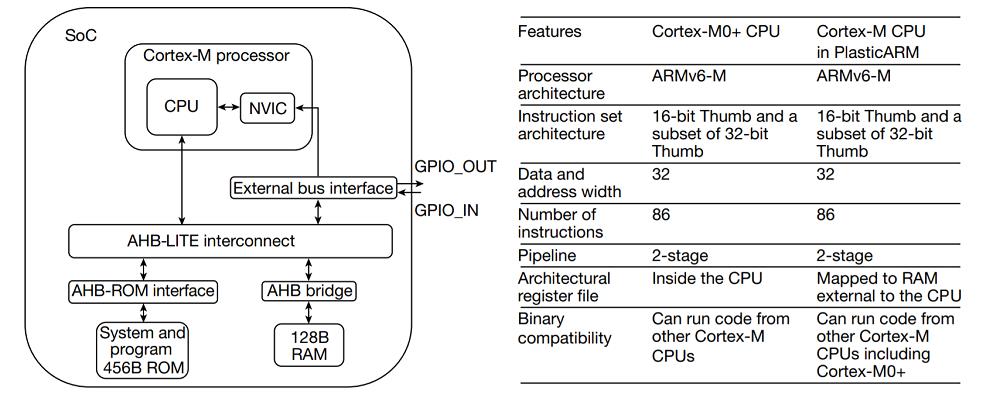

PlasticARM is mainly divided into three levels, namely 32-bit CPU;; 32-bit processor including CPU and CPU peripherals; And a system-on-a-chip (SoC) including a processor, a memory and a bus interface, namely a PlasticARM.

Its CPU is Arm Cortex-M CPU supporting Armv6-M architecture. Different from Cortex-M0+,in order to save CPU area, the registers of Cortex-M CPU are placed in RAM. Moreover, the two CPUs are binary compatible with each other, and are also compatible with other CPUs in the same architecture series.

Because the SoC is compatible with Arm Cortex-M processors, it can be equipped with existing software/tools without building a new software tool ecosystem.

The processor consists of a CPU and an embedded vector interrupt controller (NVIC) closely coupled with the CPU, which is used to handle interrupts from external devices.

In addition to the 32-bit processor, SoC also has memory (ROM/RAM), AHB-LITE interconnection structure, logic interface, bus interface and other parts.

▲ PlasticARM structure (left) and comparison with two CPU models (right)

With the advent of Plastic, wearable devices, electronic skin, etc. will usher in new development opportunities. Although its manufacturing process is lower than that of silicon-based chips, Plastic’s characteristics of low cost, low power consumption and using existing software tools may become a good opportunity for many industries to break through.

Although PlasticARM has not been commercialized, looking forward to the future era of "Everything is Smart", today will be an important node.